Space Prep provides a comprehensive suite of spacecraft and payload ground processing allowing satellite, spacecraft, and launch vehicle operators to move space hardware from the factory to the launch pad efficiently and affordably. All missions require some level of pre-launch ground processing, so Space Prep provides a full spectrum of services to prepare your payload for launch vehicle integration and flight — and post-flight if needed.

Assembly and Integration

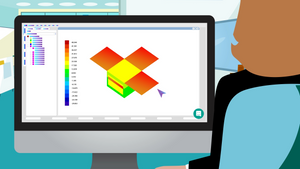

Space Prep will offer dedicated ISO8/100K cleanrooms and configurable processing spaces that support payload and spacecraft assembly, test, and checkout operations. Each processing cell supports standard power, fluids, gases, hardline and wireless connectivity, and client-specific access security.

All work areas can support enhanced cleanliness and classified operations.

Receiving and Storage

A full-service receiving dock facilitates the delivery and offloading of flight, ground, and support hardware and materials. Space Prep provides areas for high and cold storage, hazardous materials, ordnance handling and storage, batteries, and ESD-sensitive articles. Warehousing allows clients to keep their payloads and support equipment on-site until needed.

A separate Spaceport Logistics Center is also available.

Fueling

Space Prep supports spacecraft fueling with SCAPE, blast-hardened work cells, certified operators, and equipment decontamination. The service includes fueling/propellant servicing operations, ordnance operations, and protective equipment garments and cleaning. Operations support includes the use of equipment (e.g., fueling skids), garment room, and specialty support contractor engineering and technician support.

Encapsulation

A high bay processing area with an overhead crane and access stands supports payload fairing storage and preparation, integrated vehicle processing, and payload encapsulation.

| Parameter | Value |

|---|---|

| Launch Integration Location | Kennedy Space Center, Florida |

| Launch Integration Location | Vandenberg Space Force Base, California |