Rideshare on a CubeSat

Spacemanic

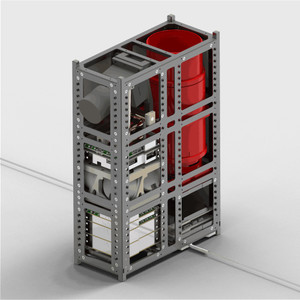

Benchmark Space Systems’ STARLING product line was developed to provide the benefits of reliable, high-precision positioning and control capability with unprecedented safety and affordability.

This innovative system uses inert, nontoxic powdered fuel that is filled before shipping and remains inert until a pressurization command is triggered on-orbit. The ability to fill, ship, store, and inhibit an assembled & fueled STARLING is “a game changer” for lowering launch manifest and operational costs, improving safety and reliability over alternatives, and providing a path to ISS compatibility.

Additive manufacturing on primary components delivers unbeatable lead time, making this the premier propulsion solution for your next CubeSat mission.

| Parameter | Value |

|---|---|

| Propellant Type | Inert nontoxic powder |

| Type | Propulsion |

| Thruster sizes | 10mN to 1N |

| Specific Impulse | 70 s (cold), 105 - 150s (warm) |

| Wet Mass | 750 g to 2700 g |

| Thrust Valve Power | < 3 W |

| Pressurization Power | 10 W |

| Minimum Impulse Bit | < 0.05 mN-s |

| Lead Time | 4 months |

| Resistojet Power | 15 to 50 W |