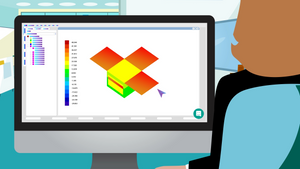

Nitrexo improves product development quality and productivity by standardising thermal engineering. With Nitrexo, satellites and launchers manufacturers reduce development time of their thermal designs by up to 50%, ensure good functioning of their equipments under space condition, and extend their product lifecycle. See below the capabilities within Nitrexo engineering services.

Thermal Engineering:

Thermal design, Spacecraft and satellite subsystems’ 3D modelling, Thermal analysis, Thermal tests, ESATAN-TMS, Systema – Thermica, Thermal Desktop, ANSYS.

Mechanical Engineering:

Mechanical design, Structural analysis, Stress analysis, Thermoelastic stress analysis, Static analysis, Dynamic analysis: modal and frequency response analysis, Buckling analysis, Nonlinear analysis, Crack propagation test, Fatigue and tolerance damage.

Optical Engineering:

Optical design, Opto-electronic design, Opto-mechanical design, Straylight analysis, Optical analysis, Optical modelling and ray tracing, Light scattering.

Expert Consultancy:

Expert thermal engineers to work on customer site or remotely for a period of time.

NanoSatellite Development:

Design, manufacturing, assembly, integration, testing, launch and ground station services.

Development of prototype subsystems:

Design, manufacturing, assembly, interation and testing.

| Parameter | Value |

|---|---|

| Software | ESATAN - TMS, Systema - Thermica, Thermal Desktop, ANSYS, NASTRAN, CODE V, Zemax, ASAP |

| Service Location | Europe |

| Type | Engineering |